One of the decisions you will need to make when buying a Porta-Blast system is what type of floor to sit it on.

If there is an existing concrete floor then the facility can be placed onto that.

If the Porta-Blast is to be used on a temporary work-site there are several options to choose from and each has its own merits.

Always bear in mind his is a temporary facility and structure. It is not designed to be a permanent set up. There will be no permanent guttering and drainage.

To reduce the risks of flooding the Porta-Blast should be positioned on as high an area as possible. Sand bags can be used all around to seal off the walls to the ground.

There are 3 commonly used floor types:

1. Concrete

2. Steel

3. Fiber board

Each of these have their own advantages and disadvantages to weigh up.

The following are some considerations when deciding on what floor material to use.

1. How long is the facility going to be in this location? Weeks, months or years?

If the facility is only going to be in position for a few weeks, or couple of months, it probably more economical to use a steel or fiber board floor. Both of these can be created with minimal preparation and can be packed up after use. If it is a longer term project, spanning months or years, a better option is a concrete floor.

2. How heavy are the parts that are going to be processed?

Heavier parts require a heavier duty floor. If the items are very light and can be easily moved in and out of the facility, a fiber floor will suffice. If the parts weigh up to several tonne a more substantial steel or concrete floor will be required to avoid floor damage.

3. How will the parts be blasted? Lying on the floor or elevated up off the floor?

Different parts are blasted differently. Pipes and steel structures are generally placed onto trestles to allow blasting and painting all over. Earth moving equipment and vehicles are naturally located off the floor. If the part is very heavy, or there is no other option but to place on the floor, then a steel floor is recommended. Concrete could also be used but it should be noted the concrete will be blasted away during blasting. This will generate a lot of dust and will eventually result in damage to the floor.

4. What type of abrasive is going to be used? Heavy steel grit or light weight plastic?

Light weight or soft abrasives such as plastics, walnut shell or glass beads will damage both the floor and structure a lot less than aggressive abrasives such as steel grit and aluminium oxide. If a soft abrasive is used, a fiber board floor can be used. If aggressive abrasives are used either a steel or concrete floor is required.

5. Floor costs.

By far the cheapest floor is fiber board. Due to the damage that is likely to occur to the floor during use it is unlikely a fiber board floor could be used on more than one project. Even if it wears out, or gets damaged during the project, fiber board is cheap to replace.

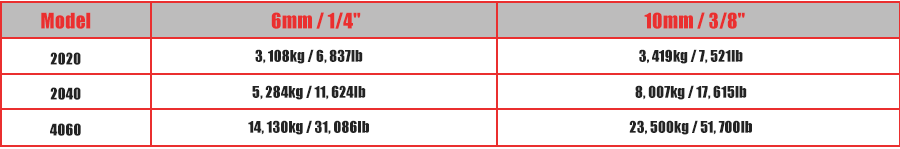

A steel floor cost is dependent on what thickness of steel is used. Either 6mm (1/4") or 10mm (3/8") steel plate is recommended. Anything less than this is likely to warp and produce an uneven floor.

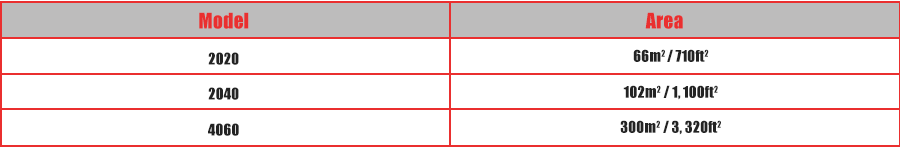

The Porta-Blast models take up the following floor areas (m2/ft2) –

Based on either 6mm (1/4") steel and 10mm (3/8") steel plate the following weights of steel would be required –

From the weights of the steel in the above chart you can calculate the steel cost based on the price of steel in your location.

Of course one of the advantages of a steel plate floor is it can be lifted up and reused at the next project location.

If the duration of the project a relatively long, a concrete floor is relatively cheap to pour. But a concrete floor is a one time use. At the end of the project the floor either has to be broken up, or the concrete pad used for another purpose.

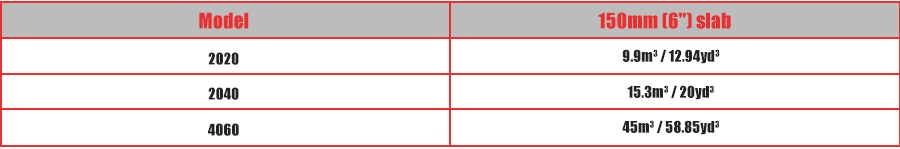

A concrete floor thickness of minimum 100-150mm (4-6") is recommended for most general applications. Based on the above floor areas the following volume of concrete would be required –

From the volumes of concrete in the above chart you can calculate the concrete cost based on the cost of concrete in your location. We are not concrete specialists but would assume if heavy parts are to be blasted and painted some reinforcing bars would be required in the concrete. Consult a concrete specialist if in doubt.

The final selection of floor material should be decided after reviewing all the above application and costing variables.

- New Mexico DMV Online Drivers License Renewal - February 22, 2023

- Can’t disable windows defender Windows 10 Support - February 9, 2023

- Hook Up on Tinder - February 6, 2023

- What floor to use - January 5, 2015

- Which abrasive should I use? - December 16, 2014

- What would you call an airless spray painting pump designed in Germany and built in the USA? - December 16, 2014

- How to dramatically increase blasting productivity - December 16, 2014

- The reason we produce TDF dust collectors - December 15, 2014

- A comparison between using glass beads and ceramic beads for abrasive blasting and shot peening - December 15, 2014

- In Abrasive Blasting, Size Does Matter - December 15, 2014