Both ceramic beads and glass beads are available in two types; as blasting beads, and as peening beads. Although in practice it is quite simple to substitute one for the other, care must be taken when the beads are used for shot peening that the beads are approved for use according to the peening specification being worked to. Ceramic beads have several advantages over glass beads.

Both ceramic beads and glass beads are available in two types; as blasting beads, and as peening beads. Although in practice it is quite simple to substitute one for the other, care must be taken when the beads are used for shot peening that the beads are approved for use according to the peening specification being worked to. Ceramic beads have several advantages over glass beads.

The advantages are mostly a result of the greater toughness and density of ceramic beads when compared to glass beads. Ceramic beads can outlast glass beads by a factor of up to 30 to 1, i.e. the life is up to 30 times greater (sometimes more!).

This feature offers several advantages as follows:

Surface finish

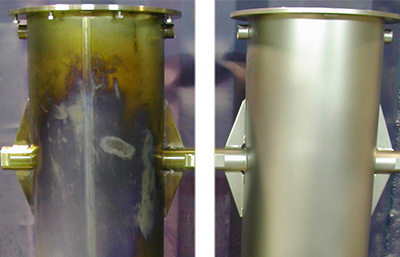

With their lower breakdown rate ceramic beads will reproduce more consistent surface finishes over long production runs. When reproducible surface finishes are required for consumer goods this is a critical factor.

When blasting with glass beads, the working mix of beads in the machine is constantly fluctuating as the beads break down and new ones are added. This fluctuation in the abrasive working mix results in higher chances of changes to the blasted surface finish.

When blasting with ceramic beads the bead breakdown rate is a lot slower. This means the working mix of beads in the machine is a lot more stable and consistent, resulting in more consistent surface finishes.

Consistent peening intensity

Again due to their lower break down rate ceramic beads are a lot more suitable for shot peening than glass beads. The objective of shot peening is to impart a layer of residual compressive stress onto the surface of a part to extend its service life. This thin compressive layer prevents the formation of fatigue cracks opening on the part surface, which cause part failure.

Anyone involved in shot peening will know that one of the critical variables that has to be controlled is the quality, size and shape, of the peening media. In an ideal world every single particle of the peening media would be uniform in size and spherical in shape.

In practice this does not happen as the media is produced containing a range of sizes and it breaks down during use.

During operation, as the media is breaking down, fluctuations will occur in the sizes and shapes of the media. Smaller and fractured particles have to be constantly removed from the peening media and replenished with new material. Broken or sharp edged particles are detrimental to the shot peening process and can cause damage to the surface.

Ceramic beads, having a lot lower rate of attrition, will not contain as many fractured particles, and a more consistent spherical particle size and shape will be maintained in the peening media. The lower the breakdown rate of the media is, the better it is for shot peening purposes.

Fingerprints and staining

Blasted surfaces, especially stainless steel items, are susceptible to unsightly fingerprints and handling blemishes. When the blasting is performed for aesthetic purposes this staining can ruin what would otherwise be a perfect surface finish. Items blasted with ceramic beads are a lot less prone to fingerprints and other handling stains than items blasted with glass beads. If the item to be blasted is likely to be frequently handled it will stay looking good a lot longer if blasted with ceramic beads.

Less waste disposal

Ceramic beads break down at a much lesser rate than glass beads. For high volume users this can make a significant difference. Depending on how expensive waste disposal is in your area, it could mean the difference between having to dispose of 1 or 2 tonnes of waste versus 10's of tonnes. This can be a significant difference.

The one disadvantage of ceramic beads is the initial cost. Although eventually ceramic beads are cheaper to use than glass they are significantly more expensive to buy. The initial up front cost is a lot higher, although in the long run the cost is lower.

As you know we have our own blasting shop. Our bead of choice; ceramic wins the day every time.

- New Mexico DMV Online Drivers License Renewal - February 22, 2023

- Can’t disable windows defender Windows 10 Support - February 9, 2023

- Hook Up on Tinder - February 6, 2023

- What floor to use - January 5, 2015

- Which abrasive should I use? - December 16, 2014

- What would you call an airless spray painting pump designed in Germany and built in the USA? - December 16, 2014

- How to dramatically increase blasting productivity - December 16, 2014

- The reason we produce TDF dust collectors - December 15, 2014

- A comparison between using glass beads and ceramic beads for abrasive blasting and shot peening - December 15, 2014

- In Abrasive Blasting, Size Does Matter - December 15, 2014