We get asked this question all the time. The answer is very simple. It depends on what you are wanting to do.

We get asked this question all the time. The answer is very simple. It depends on what you are wanting to do.

Abrasive blasting can be used for multiple purposes and what you want to achieve will determine which abrasive you should use. There is no wonder abrasive that can do everything for every application. It is very much a case of different horses for different courses.

Some typical blasting applications include:

- Preparing a surface for a coating.

- Removing old coatings, rust and corrosion.

- Removing coating to permit inspection of the surface.

- Shot peening and stress relieving.

- Surface finishing for an aesthetic finish.

- Removing old coatings prior to re-coating for refurbishment.

- Removal of carbon deposits from machinery parts.

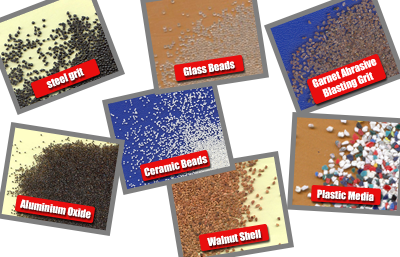

Although the fundamentals of the actual blasting are basically the same, the end result can be very different. Here is a quick run down of different abrasive types, relevant for Porta-Blast blasting, and what they can achieve.

Steel Grit – The abrasive of choice for blasting steel parts. Steel grit is extremely tough and can be recycled hundreds of times. The low breakdown rate results in minimal waste disposal of all abrasive types. Manufactured from solid steel it is also very dense. This means it hits the surface with a lot of force and results in fast cleaning speeds. Steel grit is available in various sizes to achieve different surface profiles. Larger grits will last longer but will result in deeper profiles and slower production rates. Most common sizes for the type of blasting performed in a Porta-Blast is G-50 or G-80.

Aluminium Oxide – Used for blasting non ferrous items and for removal of coatings from machine components. Alox is extremely hard and sharp and will blast very fast. Available in very fine sizes for cleaning parts but leaving a very shallow surface profile. Breakdown rate of alox is approx. 10% per cycle which means it is not a good substitute for steel grit. Along with fast cleaning speeds come one down side. Alox is very hard wearing on equipment and blast pot components need to be configured to handle it. It will even wear through tungsten carbide nozzles in a very short time.

Glass Beads – This abrasive finds the perfect balance between cleaning speed and minimal change to the underlying surface. Glass beads are minuscule spheres of glass with no sharp edges. The rounded shape leaves a very smooth surface finish. Perfect for removing coatings from non ferrous items or for blasting delicate surfaces such as machinery components, machined seal surfaces, mating flanges etc. Also ideal for aesthetic surface finishing of stainless steel and aluminium parts.

Plastic Media – The gentlest of all abrasives, plastic media is ideal for coating stripping when the underlying surface cannot be damaged. Hard enough to remove the coating but soft enough not to damage the component below. If the objective is just to get the coating off for inspection or repairs plastic media will fit the bill. It can even be used on fiberglass items such as boats to remove the paint down to the gel coat below. Approx. 15 to 20% will be lost as breakdown in each cycle. Plastic media is not cheap, so it can only be used for special high value applications that could not be blasted with other abrasives.

Ceramic Beads – This abrasive can be used as an alternative to glass beads. The applications for it are the same. A big advantage is the resulting surface finish is even smoother than that obtained with glass beads. This smoother finish is a lot less susceptible to handling finger prints. Ceramic beads will last approx. 30 times longer than glass beads. Unfortunately it is also many times more expensive than glass beads so the initial set up cost can be significant.

Walnut Shell – Similar usage as plastic media, walnut shell is a cheaper alternative. If spillage loss is likely walnut is a cost effective solution. Unlike plastic media, walnut shell is generally not approved for aerospace applications on aircraft components. As with plastic media it will strip coatings but not damage the underlying surface. The breakdown rate of walnut is quite high at approx. 20-30% per cycle.

Garnet – This is an expendable abrasive that can also be recycled up to 4 to 5 times. Garnet is a sharp natural grit that is relatively fine in size and fast cutting. Can be used for a multitude of purposes. Most common application is pre blasting steel before coating. The fine size results in lower surface profiles than steel grit. Garnet will produce very clean surfaces and can easily achieve Sa3. Breakdown rate is relatively high which results in a lot more dust to dispose of. Garnet can be used for blasting stainless steels and duplex, but not after it has been used on carbon steel. One minor advantage of garnet is it is slightly easier to clean up after blasting than steel grit as it is lighter. If the item to be blasted is a complex structure or shape, and grit entrapment is likely, garnet might be a good choice. This is because if it is exposed to rain, any residual grits will not rust or damage the coating. Any stray steel grit particles on a painted surface will rust if exposed to rain and may damage the coating.

Porta-Blast facilities can be configured for use with all of the above abrasive types.

- New Mexico DMV Online Drivers License Renewal - February 22, 2023

- Can’t disable windows defender Windows 10 Support - February 9, 2023

- Hook Up on Tinder - February 6, 2023

- What floor to use - January 5, 2015

- Which abrasive should I use? - December 16, 2014

- What would you call an airless spray painting pump designed in Germany and built in the USA? - December 16, 2014

- How to dramatically increase blasting productivity - December 16, 2014

- The reason we produce TDF dust collectors - December 15, 2014

- A comparison between using glass beads and ceramic beads for abrasive blasting and shot peening - December 15, 2014

- In Abrasive Blasting, Size Does Matter - December 15, 2014